In today’s fast-evolving world of automation and robotics, stepper motor and motors with gears have become essential components across industries. Whether you are building a robotic arm, an automated conveyor, or a precision CNC machine, understanding the unique characteristics and applications of these motors can significantly enhance performance and efficiency.

What is a Stepper Motor?

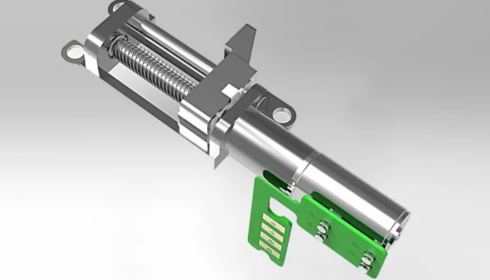

A stepper motor is a type of electric motor that moves in precise, discrete steps rather than continuous motion. This makes it ideal for applications requiring accurate positioning and repeatability. Unlike traditional DC motors, stepper motors do not rely on feedback systems to maintain position. Each pulse sent to the motor corresponds to a fixed angular movement, allowing engineers to control rotation with exceptional precision.

Stepper motors are widely used in 3D printers, CNC machines, camera platforms, and robotics. Their ability to provide consistent torque at low speeds and maintain position without constant power makes them highly reliable in automation processes. Additionally, stepper motors are simple to control using microcontrollers and driver circuits, making them a favorite choice for hobbyists and industrial applications alike.

Understanding Motor with Gear

While stepper motors excel in precision, sometimes applications demand enhanced torque and speed control. This is where a motor with gear comes into play. Also known as a geared motor, this setup combines a motor with a gearbox to reduce speed and multiply torque. The gear ratio determines the output speed and torque, allowing a standard motor to handle heavier loads or achieve slower, more controlled motion.

Geared motors are widely used in conveyor systems, electric vehicles, automated doors, and industrial machines. By integrating gears, engineers can tailor motor performance to meet specific operational requirements, ensuring both efficiency and longevity. Unlike stepper motors, geared motors may not always provide discrete steps but excel in applications where force and load management are critical.

Stepper Motors vs. Geared Motors

Choosing between a stepper motor and a motor with gear largely depends on your application requirements. Stepper motors provide unparalleled precision, making them perfect for tasks that require exact movement and repeatability. On the other hand, geared motors offer high torque output and controlled speed, which is crucial for lifting heavy objects or maintaining consistent motion in industrial machinery.

In some cases, engineers combine both technologies to harness the advantages of each. For example, integrating a stepper motor with a gearbox can deliver precise positioning along with increased torque, making it ideal for high-load, precision-driven applications like robotic arms or CNC milling machines.

Applications Across Industries

The versatility of stepper motors and motors with gears allows them to serve in numerous industries:

- Robotics: Precise movement and high torque are essential for robot joints and manipulators.

- Automation: Stepper motors control conveyor belts and assembly lines, while geared motors handle heavy-duty transport.

- Medical Devices: Accurate positioning is critical for devices like surgical robots and diagnostic machines.

- Consumer Electronics: Motors drive cameras, printers, and even smart home devices.

Conclusion

Whether you require pinpoint accuracy or high torque, both stepper motors and motors with gears play a pivotal role in modern engineering and automation. Stepper motors excel in applications requiring precise movement, while geared motors enhance torque and control for heavier loads. Understanding the distinct advantages of each type ensures optimal performance, efficiency, and reliability in any project.

By selecting the right motor for your specific needs, you can achieve enhanced performance, reduce wear and tear, and extend the lifespan of your equipment. As technology advances, the demand for innovative motor solutions will only grow, making knowledge of stepper motors and geared motors increasingly valuable for engineers, designers, and hobbyists alike.